HIGH FEED MILLING is is a type of extreme milling that allows to significantly increase the processing speed of materials in production processes.

As we mentioned in the articles dedicated to TURNING and TROCHOIDAL MILLING, thanks to these special cutting methods, it is possible to reduce the timing of mechanical machining by far, by allowing to produce more finished parts in less time.

A significant advantage for business productivity!

Why is it possible to increase production cycles when we are using high feed milling?

In this type of processing (HFM or FF) the thickness of the chip is directly proportional to the angle of attack. If the angle of attack decreases, the thickness of the chip decreases and its width increases.

This cutting condition also affects the direction of the output chip.

Thanks to this extreme machining, therefore it is possible to greatly increase the production processes and consequently the finishing and superfinishing of a greater number of components.

How the entering angle affects high feed milling: the pressure on the insert and the milling cutter

As we said, in HIGH FEED MILLING the entering angle is decisive with respect to the thickness of the chip.

Axial and radial pressure is preferable to the perpendicular one. It avoids excessive stress to the inserts and then to the milling cutter, excluding breakages of the same.

An angle of attack between 10° and 15° will be the best choice for high-feed machining.

This method combines the low cutting depth at the highest feed rate, up to 2.0 mm/tooth, allowing a greater increase in productivity.

To learn more about the advantages of high feed milling, read the article we wrote for you.

We offer some graphics to help you to better understand how to get the best results from this process:

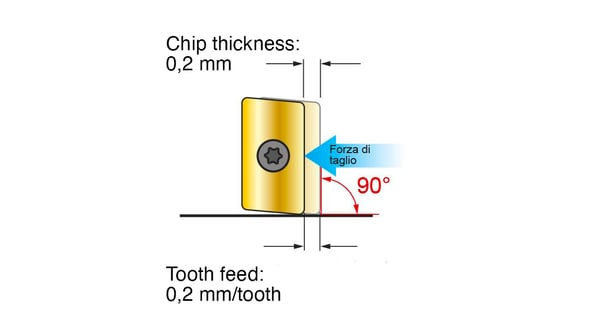

FIG. 1

In fig.1 we can see how a milling cutter with an angle of attack of 90° has no benefit of chip thinning, as 0.2 mm of feed/tooth produce as many 0.2 mm of chip thickness.

This type of machining produces a cutting force that acts perpendicularly to the spindle axis, exerting a strong lateral pressure on the cutter and consequently on the insert.

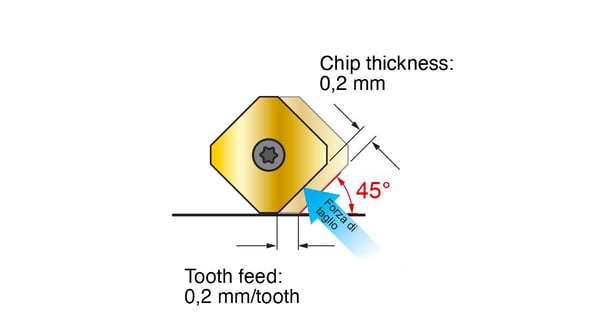

FIG. 2

In Fig. 2 we can see a milling cutter with an angle of attack of 45° and a feed of 0.28 mm generates a chip thickness of 0.2mm that allows to increase the feed, achieving a reduction in the cycle time.

The shear force acts against the spindle at an angle of 45° distributing the mechanical stress radially and axially.

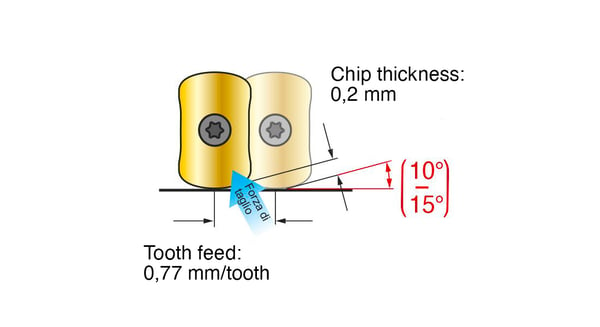

FIG. 3

Fig. 3 shows the chip thinning effect in which a feed of 0.77 mm/tooth generates a chip thickness of only 0.2mm, generally reducing the cycle time by at least 50%.

In this case the shear force is mainly oriented along the spindle axis, due to the acute attack working angle exerting pressure on the lower cutter/ insert with less shear effort.

Tips on machining and for choosing the insert

In order to avoid productivity losses, it is always necessary to identify the shape of the ideal insert in relation to the profile to be carried out in the machining.

Contact a SAU technician to avoid wasting time in choosing the right tool for high feed milling.