In our blog we talked about what high feed milling is and its advantages in use.

In this new article, we will delve deeper into the topic, so we will explain what are the characteristics of SAU high feed mills and how to make the most of them.

Read more.

SAU High Feed Mills - S1503W

HFM (High Feed Milling) or FF (Fast Feed) is an extreme milling that combines the low cutting depth with the highest feed rate, so as to allow an increase in processing speed and consequently an increase in machine productivity..

SAU is well aware of this type of processing and has created ultra-performing milling cutters.

Let’s see them together.

What are the characteristics of SAU high feed mills?

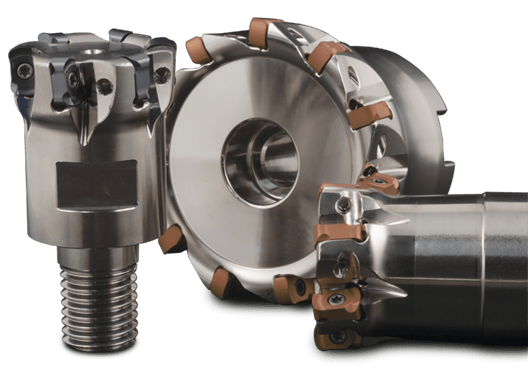

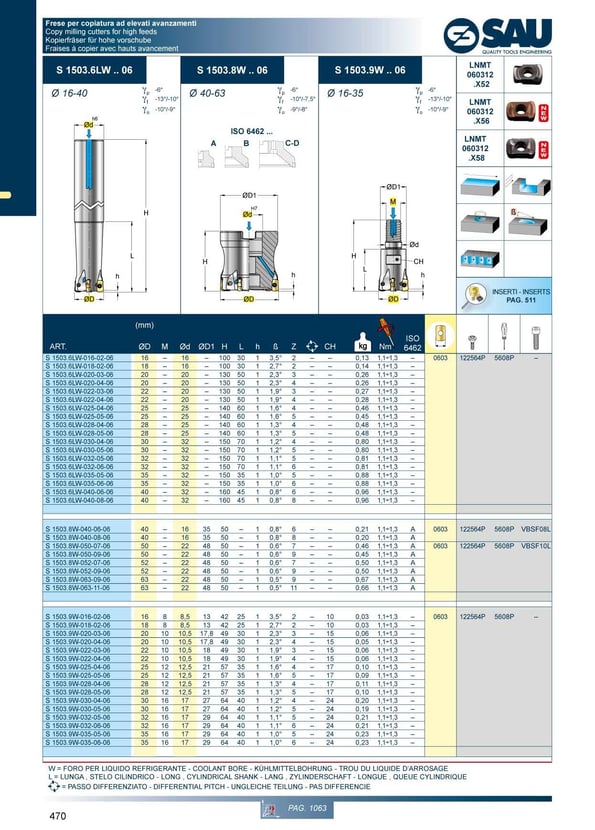

First of all, we need to distinguish between the various attachments of the SAU high feed milling:

- cylindrical shank

- front-pull

- threaded

You can see the cutters with different attacks in the pictures below.

A common feature of all SAU high feed mills is that they are ultra-resistant, thanks to the nickel-plated body ranging from Ø16 to Ø63.

At the performance level, the removal height can be up to 1 mm and the feeds up to 2.0 mm/tooth.

These features allow a sharp increase in the removal speed, compared to a traditional milling, obtaining a large chip volume.

Inserts for SAU high feed mills

For an ideal use of high feed milling cutters, in addition to traditional inserts, SAU has created new ad hoc inserts.

They are the negative inserts with 4 cutting edges, with new geometries designed for better chip evacuation and new grades to be performing in the processing of most materials.

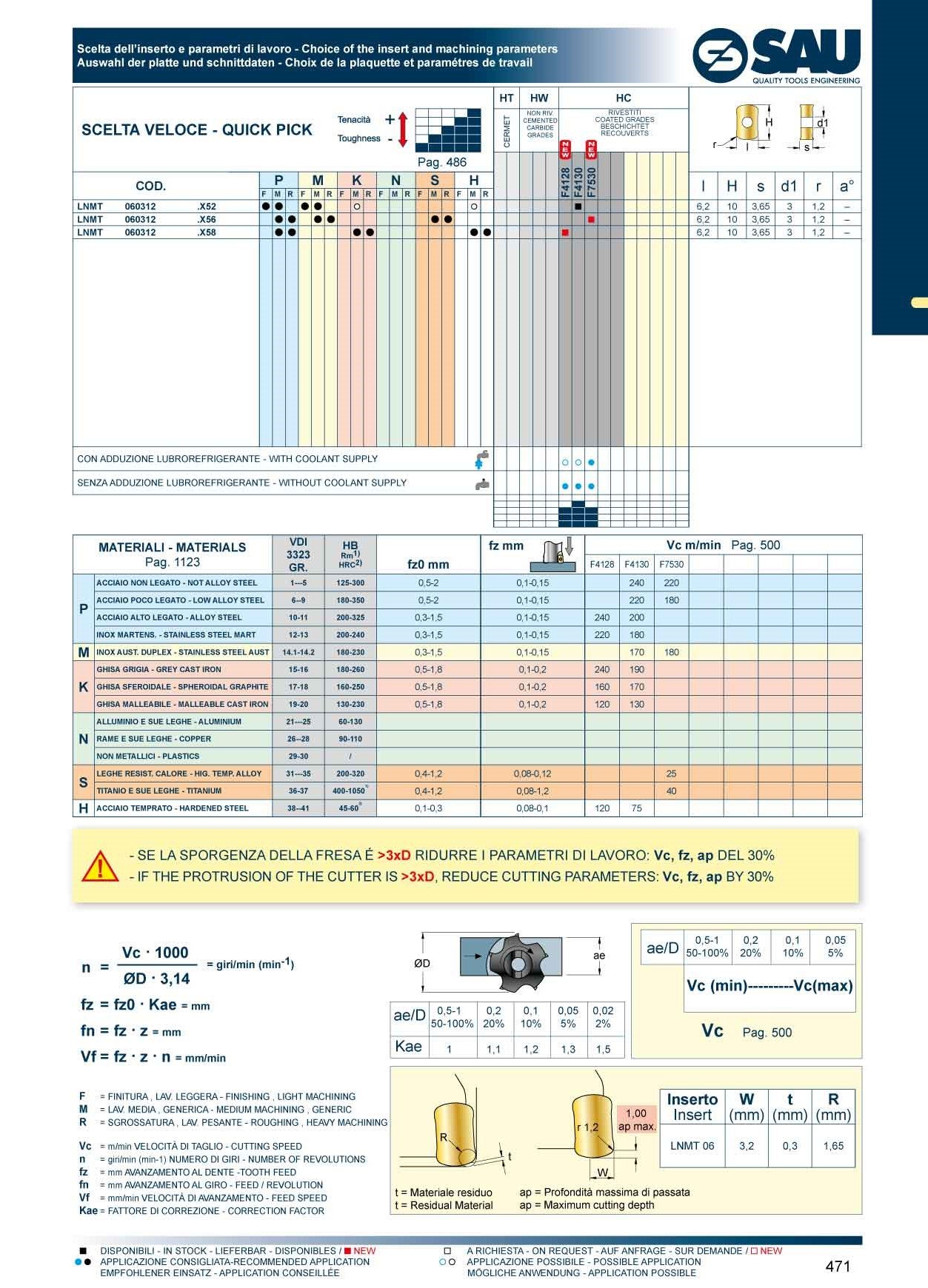

We introduce here the "old" and "new" SAU inserts, as well as for which processes and materials are indicated.

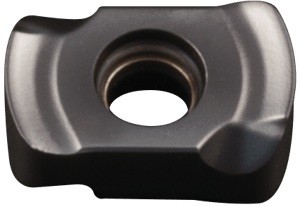

LNMT 060312.X52 F4130 inserts for high feed mills

Suitable for generic high performance machining on steels above 180HB, good applications on stainless steel and possible application on cast iron.

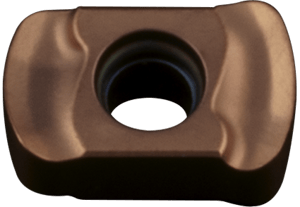

LNMT 060312.X56 F7530 inserts for high feed mills

Suitable for the processing of steel under 180HB, performing for processing on stainless steel and heat resistant alloys.

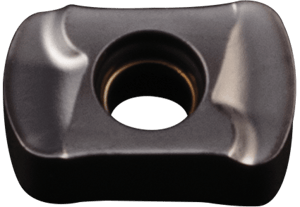

LNMT 060312.X58 F4128 inserts for high feed mills

Suitable for machining steels above 44 HRC, performing for machining on cast iron.

Conclusions

Remember that in order to avoid productivity losses, you must always identify the ideal insert in relation to the profile to be performed in the machining.

If you have doubts, do not hesitate to get advice from SAU technicians.

SAU high feed mills are renowned in Italy and abroad, as well as being one of the best-selling products.

Their special features allow:

- better evacuation

- increased tool life

- better performance

- increase of productivity

Ask our technicians for free advice and start improving your production processes with our high-feed milling cutters and inserts.

SAU Team