SAU launches new SM 4314 carbide milling cutters with cooling on the sharp.

The SAU carbide tool family is enriched with new high-performance milling cutters, to increase the speed of machining cycles and the productivity of customer companies even more.

In this short article, we will introduce you to the milling process, and then explore the features of the new SAU milling cutters.

Read on and learn how to increase your business competitiveness.

What is milling and what is milling for?

Milling is a typical technique of the manufacturing industry, which combines the art of metalworking with the precision of modern science.

The milling process consists in removing excess material from a raw surface, thanks to the use of a milling machine.

This machine uses rotary tools, milling cutters, which cut and define, to create finished or semi-finished parts of various shapes and sizes.

Milling enables the production of components with extremely tight tolerances and high-quality finishes and is essential in multiple sectors, including:

- automotive

- racing

- supercar

- aeronautics

- aerospace

- and many more.

The evolution of milling

With the introduction of numerical control machines (CNC), milling has undergone a major change, which has allowed to automate and improve the precision of the process, allowing the series production of very complex components.

Milling is the basis of modern engineering and production and is constantly evolving, just like the milling cutters that SAU regularly designs and launches on the market, in order to provide customers tools that can improve more and more the cycles of their production.

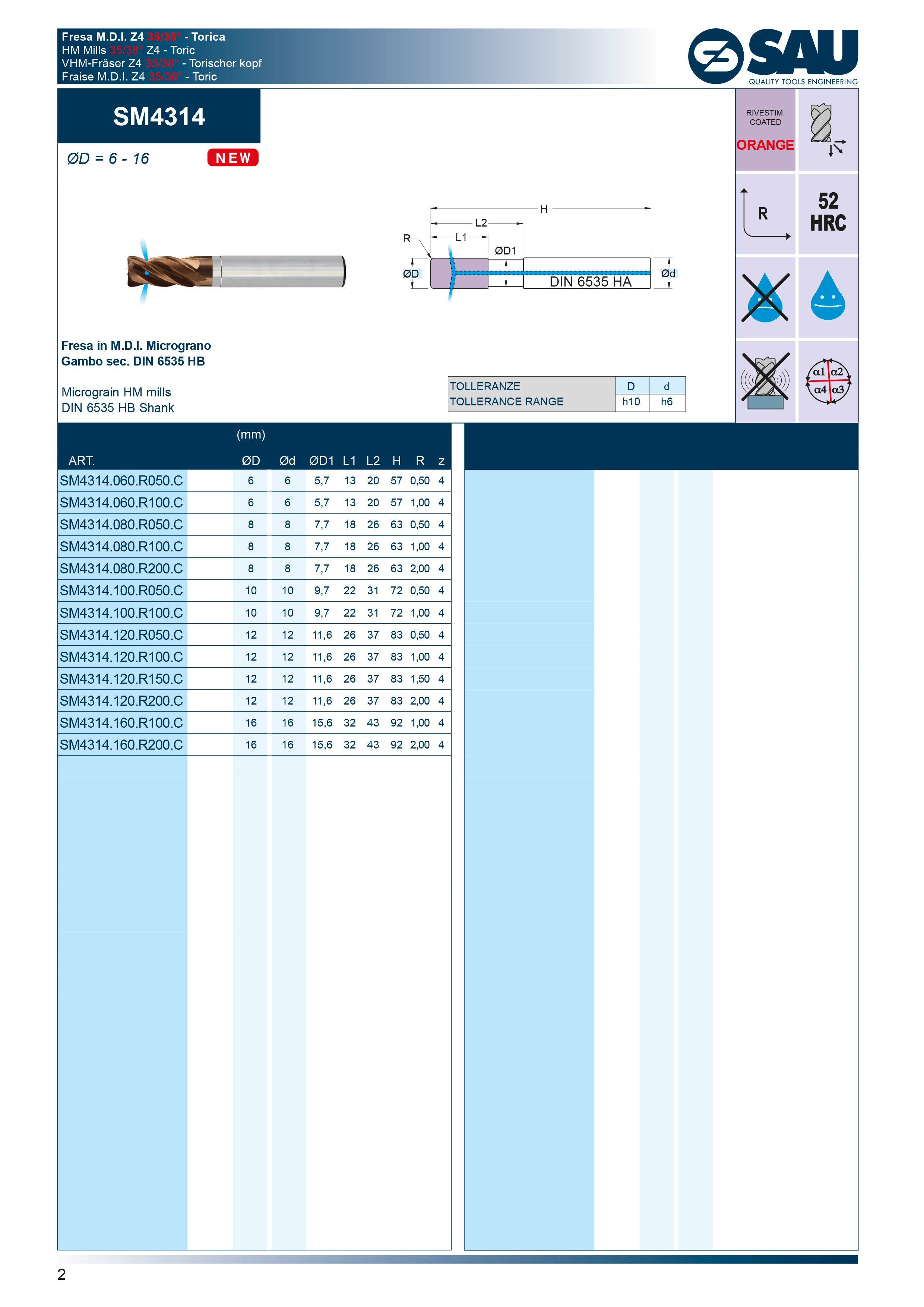

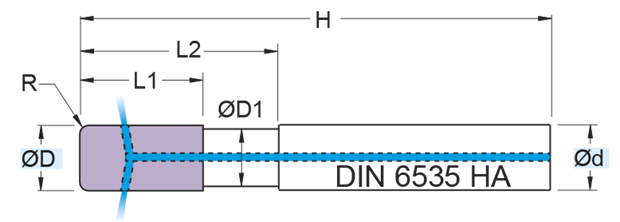

New milling cutters SM 4314

The new carbide cutters SM 4314 have the holes for lubrication directly on the cutting edge, a peculiarity that differentiates them from other milling tools for solid carbide on the market.

Thanks to this innovative positioning, the temperature remains constant and the chip heat can be better controlled and the milling process can be speeded up.

SAU is always attentive to the demands of the manufacturing industry, which requires optimized and faster processes.

This is how he designed and built from scratch the new SM 4314 carbide milling cutters for the processing of:

- steel

- stainless steel

- super alloys

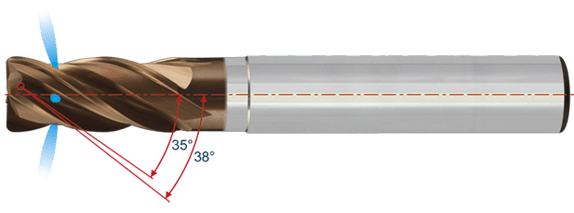

SM 4314 milling cutters have a differential angle (Z4 35/38°), carbide Z4 toric with internal coolant.

The milling cutter has variable angle and irregular division differentiated.

SM 4314 carbide cutters can be used for shank strength tightening, shrinking fit and collect holder.

Advantages of the new milling cutters

As mentioned, the structure of the new integrated carbide cutters from SAU allows for many advantages including:

- finishing and roughness optimization

- increased processing speed

- reduction of production cycle times

- increase in tool life

- increase in productivity.

Conclusions

The new carbide milling cutters SM 4314 are the result of the decades of experience of SAU Technicians.

If you want to optimize and make more competitive milling operations on steel, stainless steel and super alloys, do not hesitate to contact them and learn more about the features of the new SM 4314 carbide milling cutters.

We work every day to increase the productivity of your machine tools.

Trust those who have served the most important manufacturing industries in Europe for more than 40 years.

Contact SAU technicians here: https://www.sautool.com/en/contact-us

And increase the competitiveness of your company.

SAU - Quality Tools Engineering since 1982.