In the machining of small components, there may be the need for high precision and high productivity in series and traditional lathes can’t always guarantee maximum efficiency.

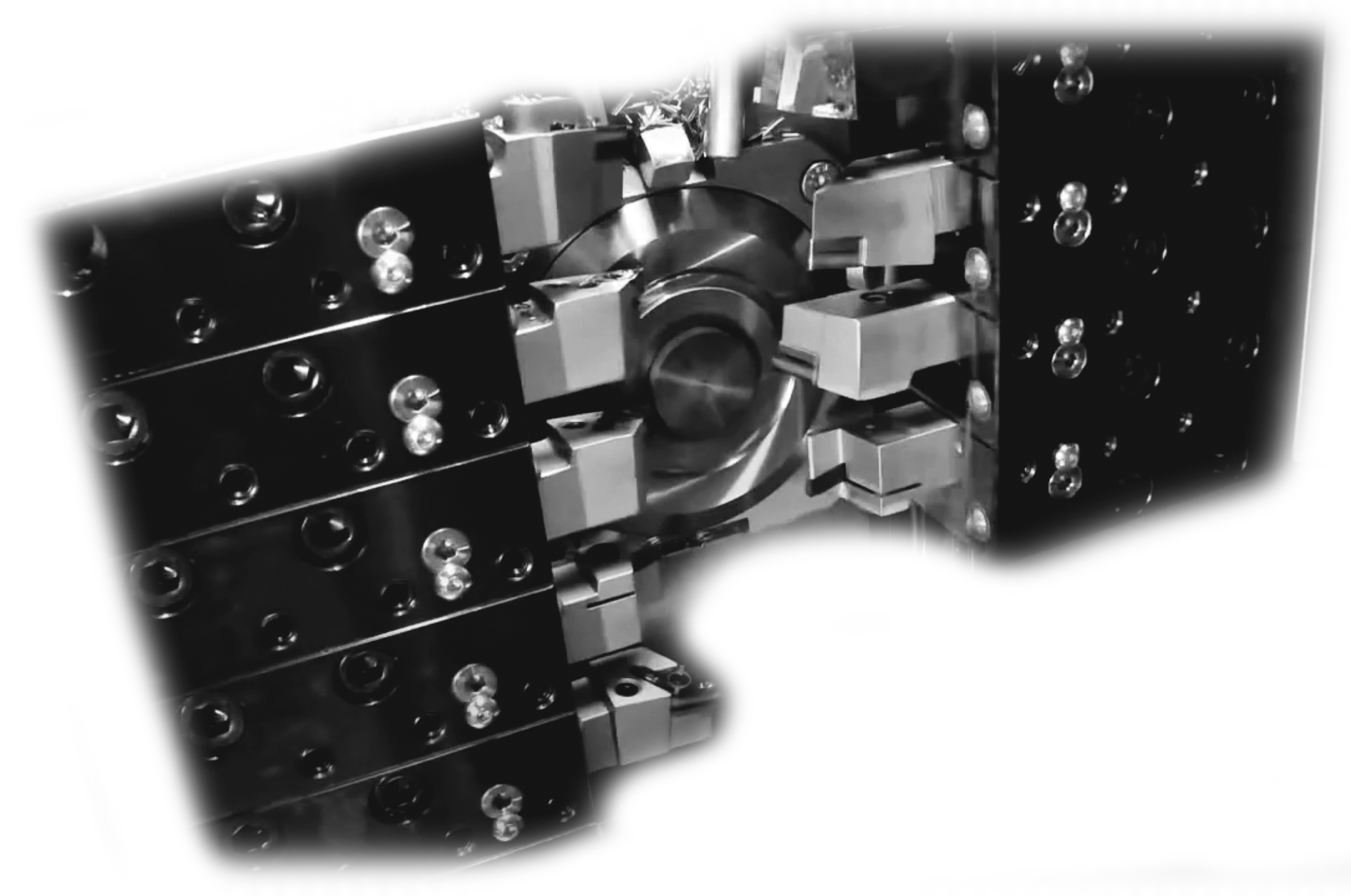

Instead, there are machine tools, which exploit the axial sliding of the piece, allowing it to work on very tight tolerances and very long pieces.

It is about a sliding headstock machine.

Let’s see how they work.

What is a sliding headstock machine?

The

sliding headstock is a very different machine tool concept from

the traditional lathe.

The

sliding headstock is a very different machine tool concept from

the traditional lathe.

The component is guided, inside the machine, by

a bush that moves the bar, while the tools are stopped, with a significant increase in the stability and precision of the machining.

The difference with traditional lathes is in the possibility of having different axes, so you can carry out

more processing at the same time, on more faces of the same piece.

A great plus!

The sliding headstock machines are divided into two large families:

The sliding headstock with cams is the first version of this type of machine, while the more modern version that allows more flexibility is the CNC headstock, which does not need to change the cams to change the production cycle, with a significant increase in productivity.

Advantages of sliding headstock machine

The benefits in the use of the headstock machine are many:

- greater precision on small components

- maximum stability

- maximum precision on long pieces

- simultaneous processing on several faces of the same piece

- more productivity.

Let's see them in detail.

Greater precision small components

Thanks to the same structure of the headstock machine, it is possible to work on very small parts with maximum precision. The tolerances are very tight and are ideal for machining components for hydraulics, automotive and many other industries.

Maximum stability

Thanks to the guide bushings, the component is brought to the tools, taking advantage of the Z axis of the machine. This movement ensures maximum stability in processing.

Greater precision on long parts

If the sliding headstock machines are intended for the processing of small pieces, another use is that of very long pieces, which can hardly be processed in a traditional lathe.

Thanks to the internal bush and the axial movement, the headstock is perfect for machining components with these characteristics.

Simultaneous processing on multiple faces

As mentioned, the other fundamental advantage of this machine tool, compared to a traditional lathe, is the possibility to carry out several operations, with as many tools, simultaneously. A very considerable benefit.

Increased productivity

The structure of the machine allows to speed up the production of large batches of components, maintaining high precision and safety.

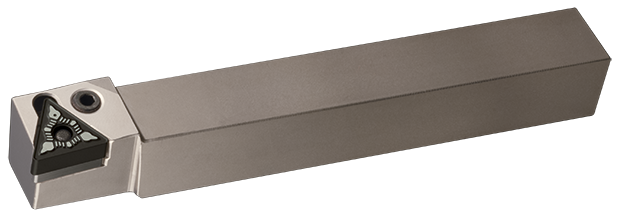

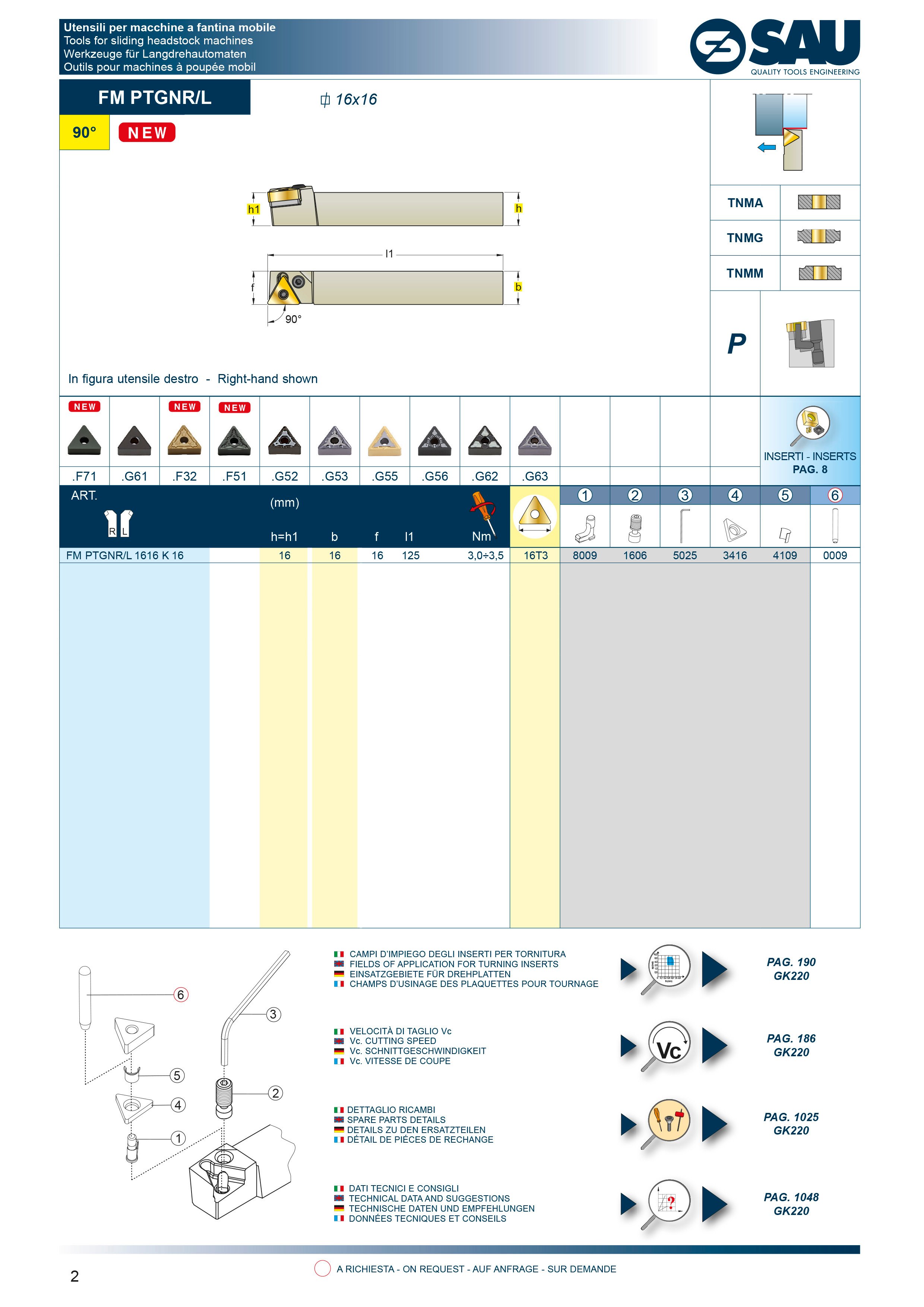

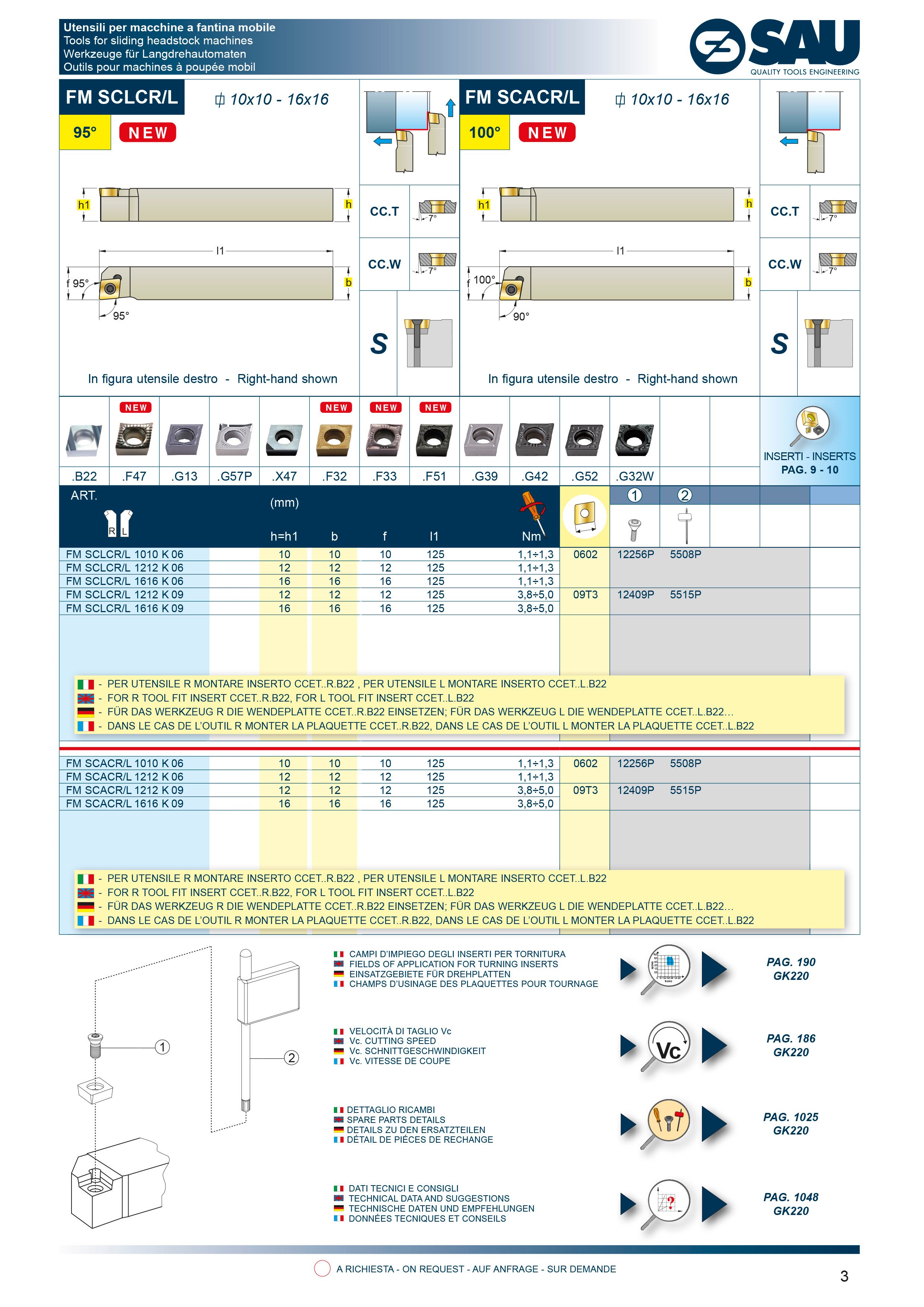

New tools for SAU headstock

We might wonder if such a particular machine should use special tools. The question is more than appropriate.

In the SAU experience, there have been many requests for special tools for headstock machines and today SAU has a range of tools for all major machining, as well as new designed.

For example, tools have been added that mount the negative insert (TNM..) which is not so common, born as special and then kept as standard.

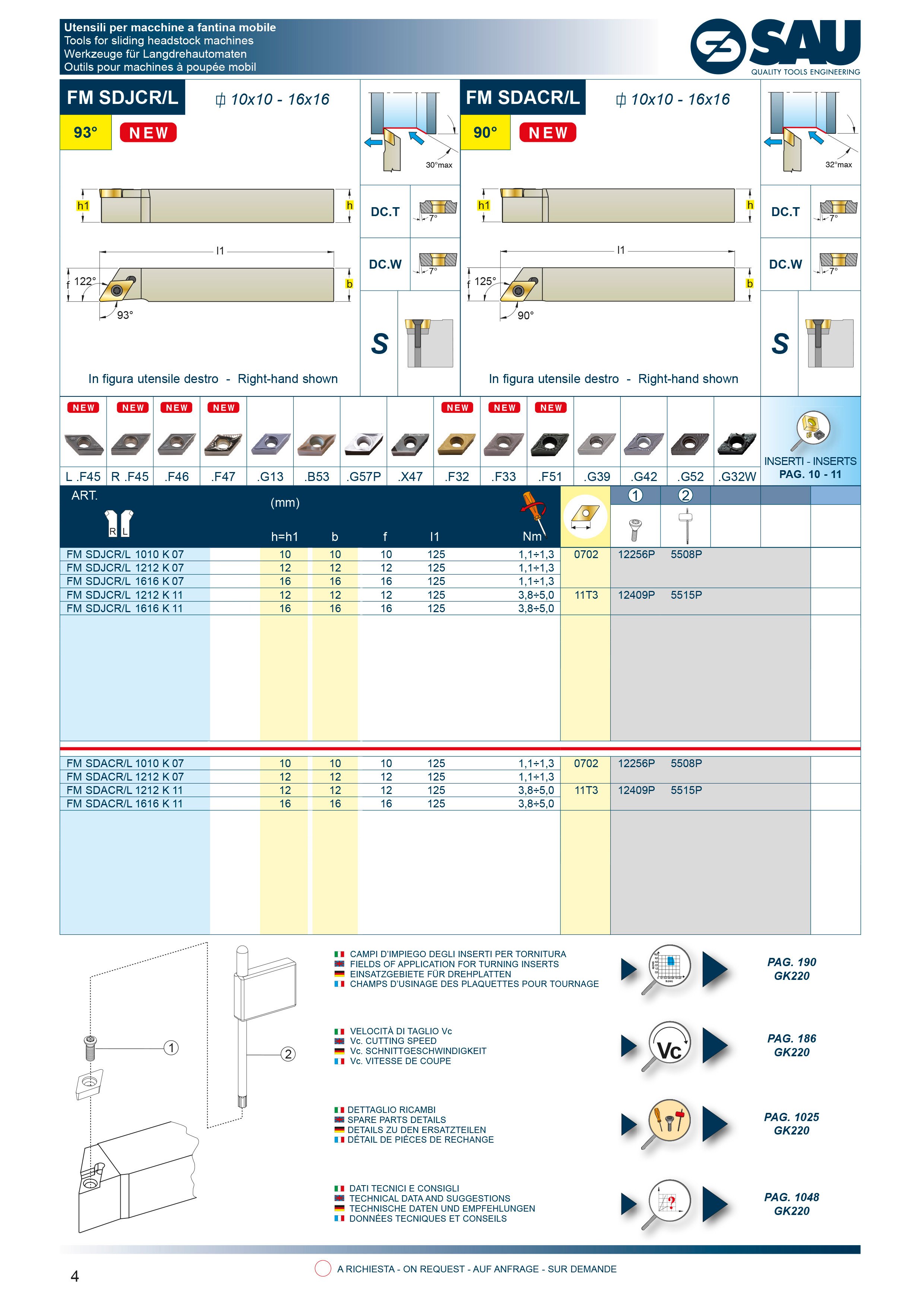

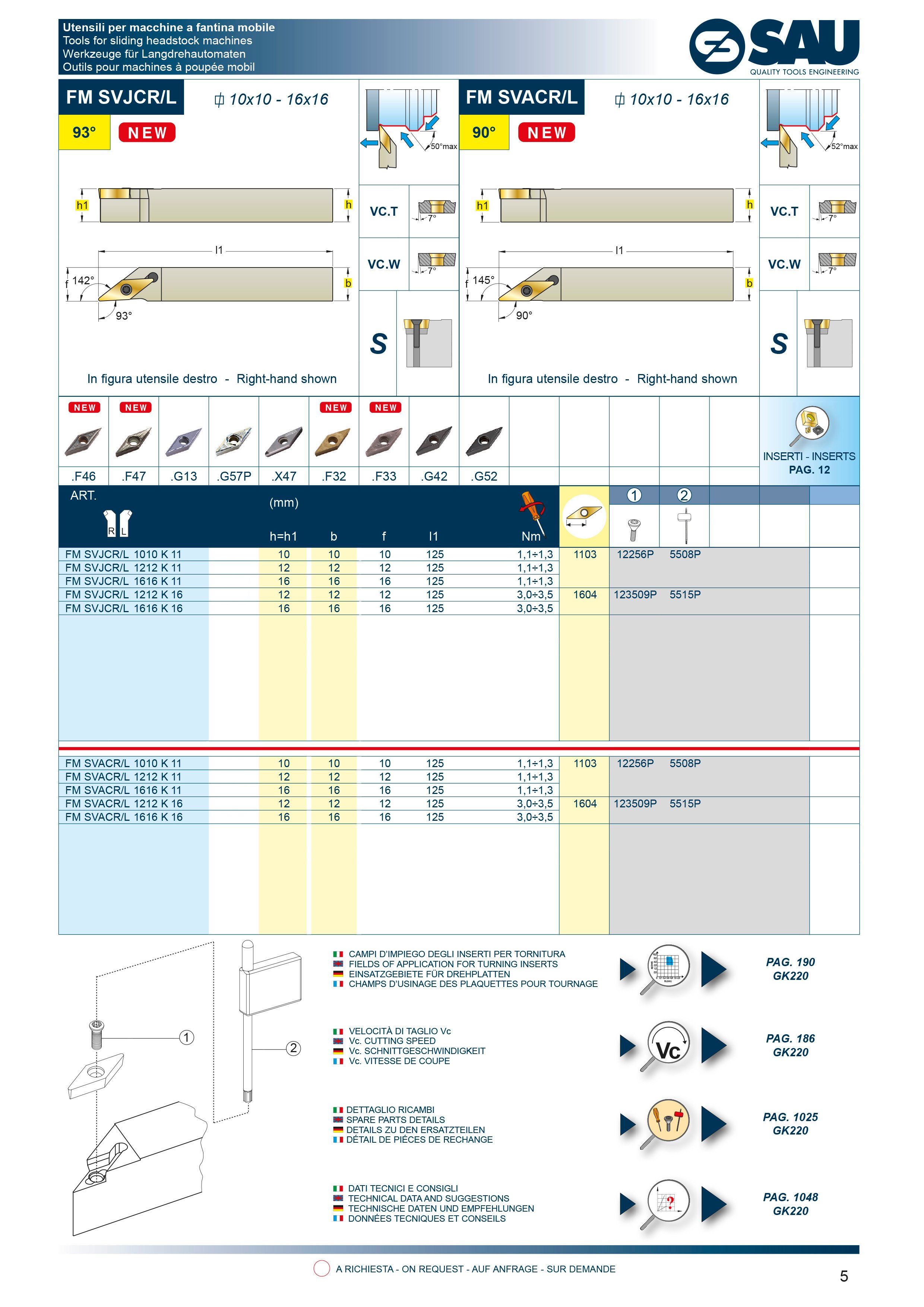

The dimensions of the tools available range from 10x10 to 16x16 with "F '' flush stem to have the minimum possible encumbrance, angles of attack of 90°, 93°, and 95°, they are all nickel-plated, to offer maximum strength and durability.

We invite you to deepen in the datasheet that you can find below.

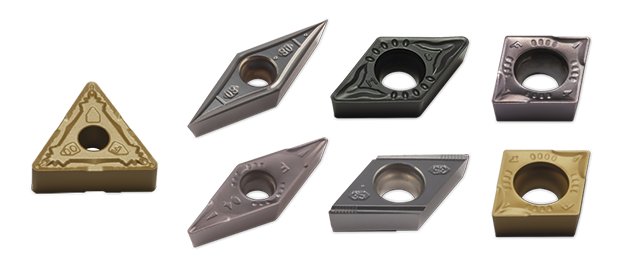

Inserts for headstock tools

Inserts for headstock tools

Also here SAU offers a new

range of inserts.

SAU has specific geometries for machining of superfinishing, perfect to optimize and exploit the headstock lathe.

We invite you to deepen the features, for example:

- Inserts TN (negative inserts corner 60° - turning with 6 cutting edges)

- Inserts CC (insert corner 80° - for turning and facing)

- Inserts DC (insert corner 55° - entry corner 30°)

- Inserts VC (insert corner 35° - entry corner 50°)

Depending on the angle, there are several tools and we remind you of the possibility to customize them according to your needs.

Download the catalogue here: https://www.sautool.com/en/download

Conclusions

If you need to carry out several operations at the same time, on small and/or long components, the advice of the SAU Technical experts is to use the headstock machines and new specific tools.

Do not hesitate to contact the technicians for advice. They are at your complete disposal here: https://sautool.com/en/contact-us

Call them for an immediate and free phone consultation.

SAU - Quality Tools Engineering since 1982.