In the article that you can read here about shrink fitting we have explored the peculiarities of this working tools clamping technique.

What are the advantages?

Just below you will find the benefits of this technology to optimize lean, fast and decluttering machining:

- Quick tool insertion and extraction

- High radial clamping force

- Significant reduction of clamping force at high speed

- Longer life for the tool and the spindle

- Excellent surface finish of the processed material thanks to the high rigidity of the clamping system and the reduced tolerance of concentricity

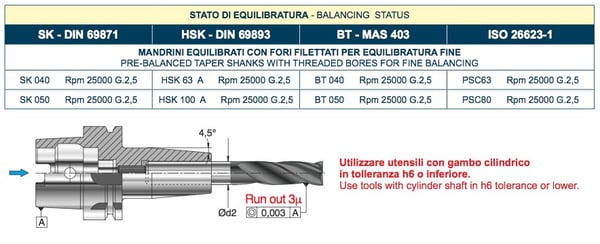

- Reduced spindle size and compact tool seat profile that minimizes encumbrance; the tool seat has an angle of 4,5°, as per regulation DIN 69882-8.

- Locking of hard metal and super fast steel tools with h6 shank tolerance according to DIN 6535HA and DIN 1835° on the same spindle.

- Spindles with high durability and shape stability, thanks to the use of special high temperature resistant steel and special heat treatments

- Concentricity values in spindle-tool coupling lower than 3 MICRON with absolute repeatability over time

- Spindles designed with symmetrical geometry without imbalance masses suitable for high-speed machining, for which high dynamic equilibration is required

- High flexibility thanks to the possibility of combining spindles with extensions and accessories of various types

Shrink fitting spindles

This type of spindles has been specifically designed to minimize the encumbrance in the cutting area.

The overall dimensions comply the regulation DIN 69882-8 and a wide range of dimensions is available with insertion holes from Ø3 to Ø32, in the short and long version.

CT spindles represent the ideal balance between overall dimensions, rigidity, torque transmission and are the best choice to use the technology of shrink fitting.

The extendable shrink fitting spindles

It is possible to use the extendable CT spindles to exploit the adjustment of the projection of the tools with long shank, in order to allow an optimal use of the tool.

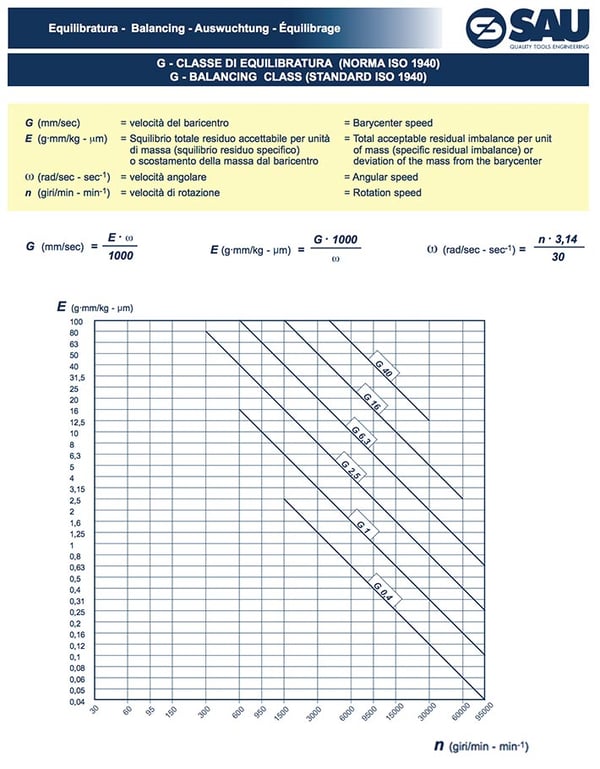

The most important advice is to improve the balance in order to preserve the durability of the inserts, have less mechanical stress of the machine and improve the roughness of the worked surfaces.

The CT spindles in the extension version are ideal for using cylindrical extensions with thermal shrinkage or cylindrical extensions in anti-vibration carbide.

The processes for which this version of spindle is particularly recommended are finishing milling, drilling and holes boring.

We always remember you to use inserts with cylindrical shank in tolerance H6 or lower.

Don’t hesitate to contact the SAU technicians for any further information

Optimise the choice of the spindle and tool for your machining.