Shoulder milling cutters and the new S9006...10 with its applications

Shoulder milling cutters are essential tools for the manufacturing industry, used to create flat surfaces and 90-degree angles.

Those looking for stability in operation and flexibility in use of different materials can find a perfect ally in these milling cutters.

The advantages of shoulder milling cutters

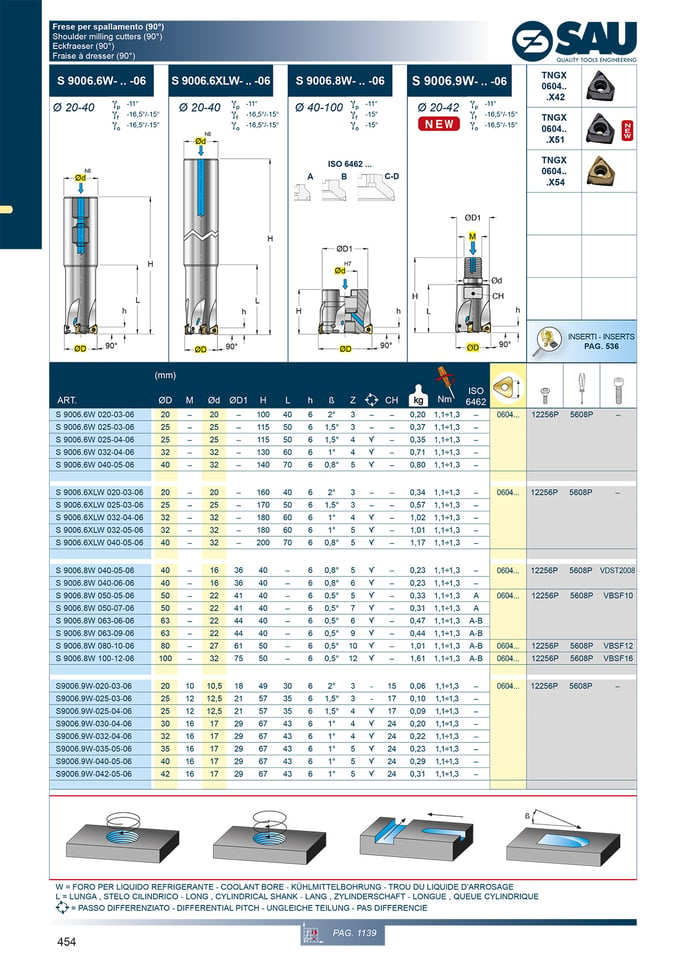

In this article, we will explore the range of SAU shoulder milling cutters, starting from traditional models such as the S9003, S9004, S9005 and S9006 series, and then explore the new features introduced with the S9006...10.

We will also analyze the specific inserts depending on the material and the advantages that these milling cutters offer in different industrial applications.

Shoulder milling cutters are the most versatile and used, offering numerous advantages over other milling solutions, making them an ideal choice for many industrial sectors.

The main benefits include:

-Precision machining: thanks to their geometry, our shoulder milling cutters are able to achieve good surfaces and excellent perpendicular levels at 90 degrees, even in complex milling operations.

-Versatility: with a wide range of inserts available, these milling cutters can be used on a variety of materials including steel, stainless steel, cast iron and aluminium, making them highly flexible depending on the material to be processed

-Improved heat management: The advanced design of these inserts allows for better heat management during cutting, reducing wear and improving surface finish quality.

The range of shoulder milling cutters S9003, S9004 and S9005

The S9003, S9004 and S9005 are traditional shoulder solutions designed for operations that require robustness and reliability.

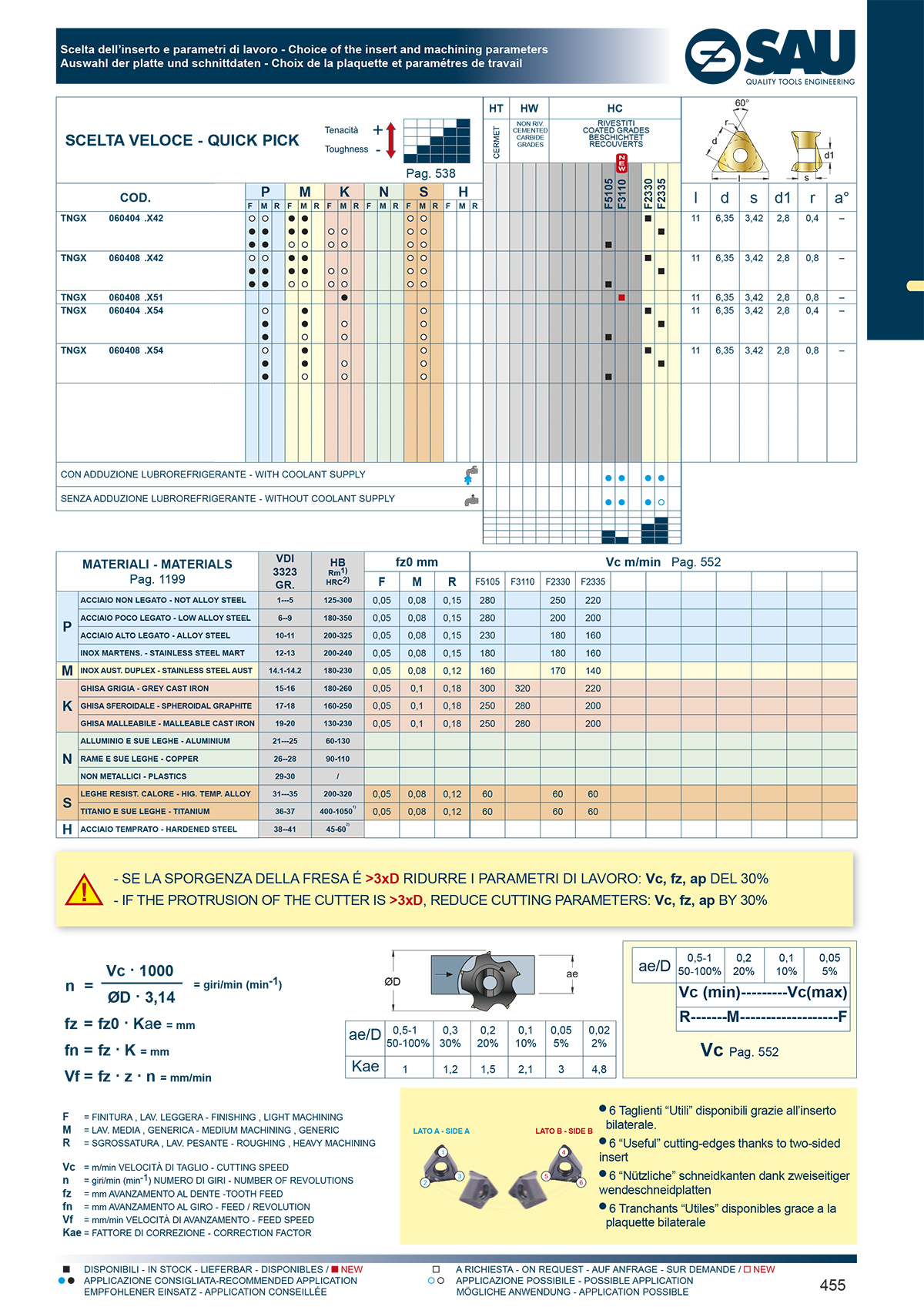

With a diameter range from 20 to 160 mm, these milling cutters are compatible with a series of inserts, offering three or four cutting edges for increased durability.

These inserts, available in different grades, are specifically designed to optimize performance on various materials.

Thanks to the flexibility of these inserts, S9003, S9004 and S9005 milling cutters are used in a variety of industries, from precision machining to large-scale industrial production.

To learn more about traditional shoulder milling cutters, visit the page on our website:

www.sautool.com.

The new S9006...10 milling cutter: a step forward

With the introduction of the S9006...10, SAU has further improved the performance of shoulder milling cutters by introducing new dimensions and greater flexibility.

This new milling cutter is designed to guarantee excellent results even in the machining of overlapping shoulders, thanks to its geometry optimized for multiple machining.

With repeated passages, the S9006...10 guarantees a flawless finish and high precision.

The wide range of inserts available in different gradations, designed to achieve maximum performance on various materials.

- F5105: for steel

- F2330: suitable for both steel and stainless steel

- F2335: More resistant grade, ideal for hard and stainless steels

- F3110: specific for cast iron.

One of the main innovations of the S9006...10, as mentioned above, is the introduction of the aluminium-specific grinding and flattening insert, the TMGX 100608.X57P, grade N3620, which offers an exceptional finish on non-ferrous materials and reduces burr formation.

This feature makes the milling cutter ideal for high precision operations on aluminium and other similar materials.

Conclusions

The SAU series of shoulder milling cutters, with the introduction of the S9006...10, offers cutting-edge solutions for precision machining.

The new dimensions, together with the possibility of using inserts specific to various materials, make these milling cutters an indispensable tool for increasing productivity and quality in milling operations.

If you have any questions or want to know more about which milling cutter or insert is best suited for your needs, contact our experts today.

https://sautool.com/en/contact-us

Sau team

SAU - Quality Tools Engineering since 1982.