The Mini SEC in Solid Carbide can be considered a "little brother" of the SEC and it also allows more machining on the same product/ material without having to use different tools.

With the Mini SEC in Solid Carbide you can have many advantages:

- availability of a tool for each type of processing

- only one setting and not one for each tool

- no waste of time

- no waste of energy by operators

SAU wants to solve the problems related to the various downtimes for new settings, machine set-up times and costs in the purchase of more tools, to remedy all this, SAU has designed a multifunctional tool to facilitate the needs of operators who have to perform several mechanical operations on the same product.

The research and development department of Sau has identified the SAU Mini SEC Solid Carbide Multifunctional Tool as the ideal tool to allow multiple machining operations with a single tool.

Keep reading.

Multifunctional tool for drilling and turning SAU Mini SEC | Features

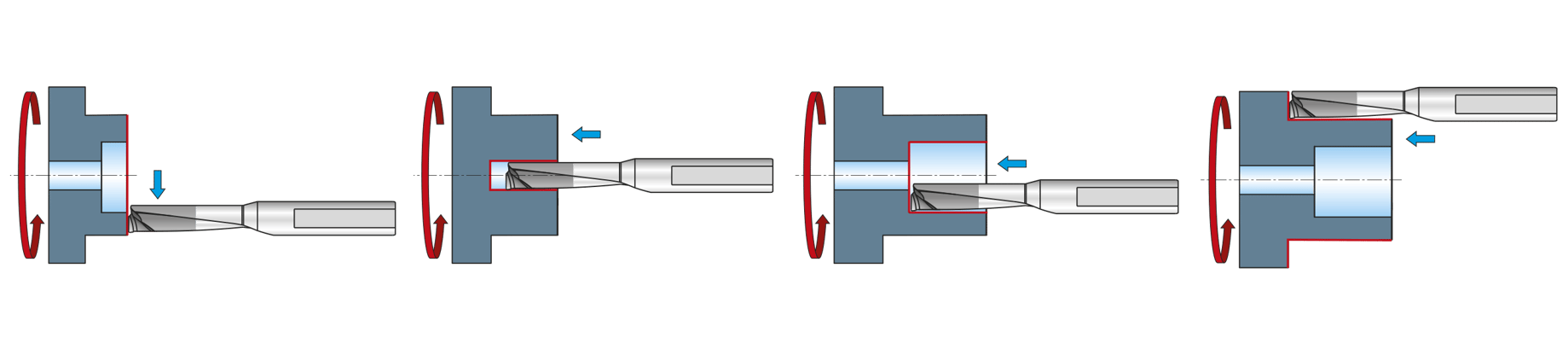

This latest generation tool can be used for up to four precision machining operations with a single tool:

Drilling: characteristics of the Mini SEC in solid carbide

The tool is available in two versions 2.25xD and 4xD, with a range that includes Ø4 - Ø5 - Ø6 mm with 90° depth.

The Mini SEC in Solid Carbide SAU have two grades of tool, one uncoated N3635 for applications on non-ferrous materials, the other with coating F7835 suitable for all machining on all materials indicated ISO P M K S.

The Mini SEC in Integral Carbide are equipped with a hole for the supply at the center, to optimize the control of the chip and improve the tool life while improving the drilling.

Turning: characteristics of the Mini SEC in solid carbide

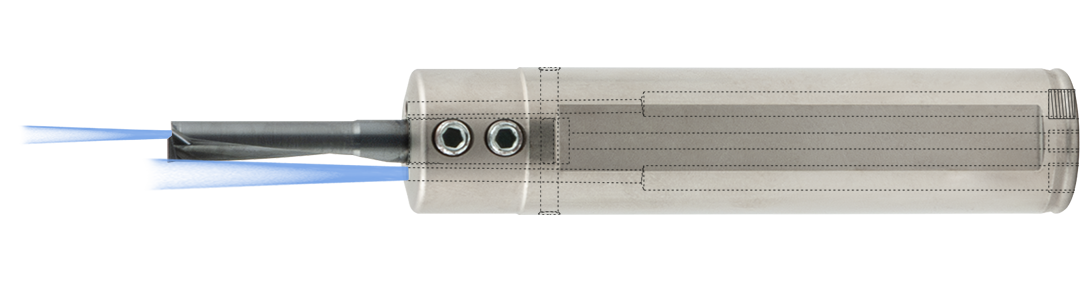

When it comes to internal, external or facing turning, the SAU S100-TS-06 tool holder is equipped with an additional hole on the side of the tool, this improves finishing, chip control and increases tool life.

SAU Tool Holder S100-TS-06

The tool holder S100-TS-06 is nickel plated with 3 supply holes with 2 side holes and one central hole, on this tool holder you can apply all Sau mini tools.

The Sau mini tools have a connection of Ø4 - Ø5 - Ø6mm with the various tool holders S100-TS-06 starting from Ø12 mm to Ø25 mm.

Advantages in the use of integral carbide Mini SEC

The advantages of using the SAU Mini SEC tool are many:

- speed of equipment

- reduction of tool change times

- Avoid multiple tool settings

- Easier use of turret tools

- Increase availability for the use of other tools

To switch from one machining to another, just set the CNC program, a breeze!

Fields of application of Mini SEC in Solid Carbide

The Mini SEC in solid carbide can be used on a variety of materials, they are especially suitable for steel, stainless steel, cast iron and aluminium.

The SAU Mini SEC in solid carbide offer excellent performance in super alloy machining.

Fields of application of Mini SEC in SAU Solid Carbide

The Mini Sec can be applied in all processing of all sectors, indicated on machines at Swiss-type lathe, CNC and manual turning, machining and production of small components that require great precision, suitable for both small and large batches of production.

Conclusions

Mini SEC in solid carbide optimizes the capacity of the machine tool making it more efficient. Savings on tool costs and reducing processing times are their best advantages, all guaranteeing a product of maximum precision and great quality.

To find out more about our Mini SEC and how they can improve your production processes, contact us today.

Sau Team

SAU - Quality Tools Engineering since 1982.