Numerous problems can arise during clamp tooling operations in mechanical processing, the most important of these is the difficulty of repeating the positioning of the piece.

With the help of SAU magnetic parallel bars, this is solved by ensuring always equal height positioning.

Continue reading.

The characteristics of Magnetic Parallel bars

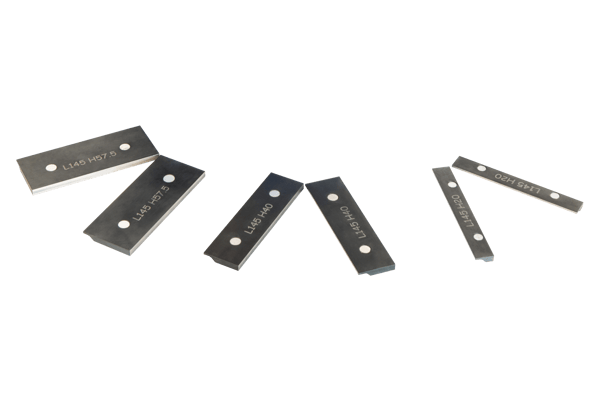

The magnetic parallel bars are made of C45, are heat treated 36-42 HRC and have to be heat treated with a nitrocarburization treatment with a thickness of 0.3 mm which gives a further hardness of up to 46 HRC.

This treatment gives a characteristic burnished color to the parallel bars.

The use of Magnetic Parallel bars

Magnetic parallel bars are used as a precision support for the clamping of the pieces.

The pieces are blocked with extreme precision for machining, allowing the height to be repeated over time, this also facilitates future tooling for machining the piece.

Magnetic Parallel Bars: which vices can be used on

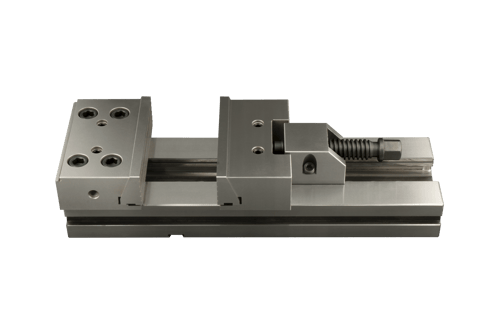

Magnetic parallel bars can be used on all vices with jaws greater than 145 mm in width, but can also be used on jaws of smaller width.

The SPM-CN Magnetic Parallel bars mounted on the MS... precision modular clamps from SAU are the perfect combination, allowing great performance when placing the machine with an excellent quality-price ratio.

Dimensional characteristics of Magnetic Parallel bars

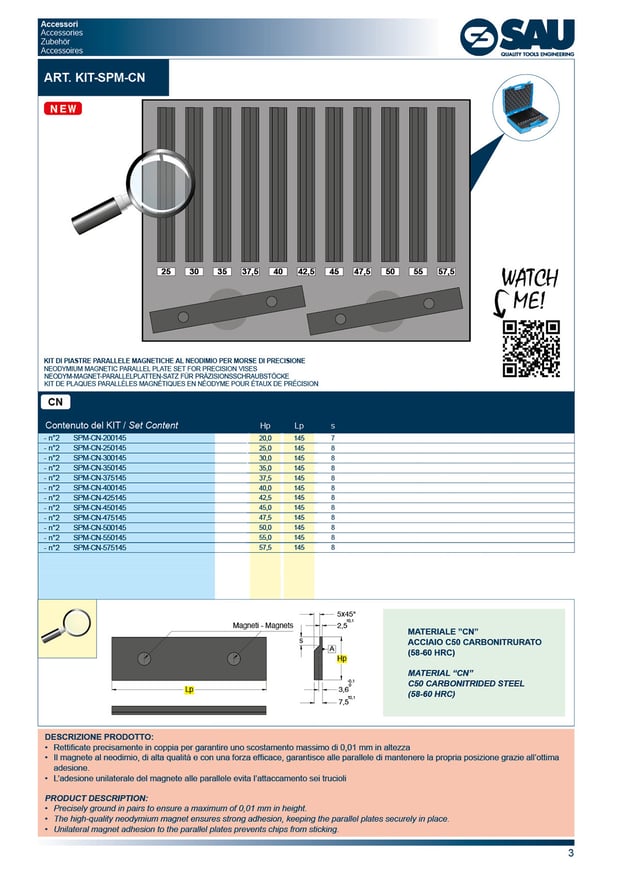

The magnetic parallel bars of Sau SPM-CN have heights with 12 dimensions from 20 to 57.5 mm with an accuracy of 0.03 mm, they are realized in pairs to ensure absolute uniformity of the final product.

The magnetic parallel bars of Sau SPM-CN have 2 thicknesses, on one side 2.5 mm which allow the pieces to be machined as close as possible to the vice, while on the opposite side they have a width of 7.5 mm which guarantees greater support and stability.

The width is 145 mm and the 2 neodymium magnets positioned on the face in contact with the clamp jaw guarantee precise adhesion.

Magnetism is present only on the side in contact with the jaw, it is not transmitted to the rest of the parallel, the chips will never stick during processing.

Magnetic Parallels: processing materials

Magnetic parallel bars have universal use and can be used on any type of material, from iron to wood, from aluminum to thermoplastic materials.

SAU Kit-SPM-CN

Sau's Kit-SPM-CN is supplied in a comfortable case with a complete range of 12 pairs of parallel bars. Order, cleanliness and functionality for use in the workshop are the advantages that our kit guarantees the user.

Sau's SPM-CN Kit is always available for delivery within 24 hours in Italy and 48 in the rest of the world

Conclusions

The versatility and ease of use of the SAU parallel bars make them indispensable in all workshops that use vices for locking the piece

To find out more about our SPM-CN magnetic parallel bars and how they can improve your production processes, contact us today.

Sau Team

SAU - Quality Tools Engineering since 1982.