What is honing and what is it for: honing of SAU

The honing is a fundamental part of inserts and tools for metal machining, essential to ensure uniformity of tool life and improve performance of carbide cutting tools. But what exactly is the honing and what is it for?

In this article, we will explore this process in detail, its impact on tools and the benefits it offers in terms of efficiency and durability of machining tools.

Keep reading.

What does honing mean?

The honing is a step that is given to the cutting edge of cutting tools, such as milling cutters, drills, inserts and other tools used in various machining processes.

This process consists of reinforcing the cutting edge by a slight chamfering or rounding, which can vary from a few thousandths to tenths of millimeter depending on the type of processing and the material.

Honing gives to the cutting edge of the tool a more homogeneous and robust thread, improving strength and stability during the cutting operation.

This results in a more precise control of the cutting itself and a longer, consistent tool life.

The differences in honing depending on the tool

Honing is a process that varies greatly depending on the type of tool and its application.

For example:

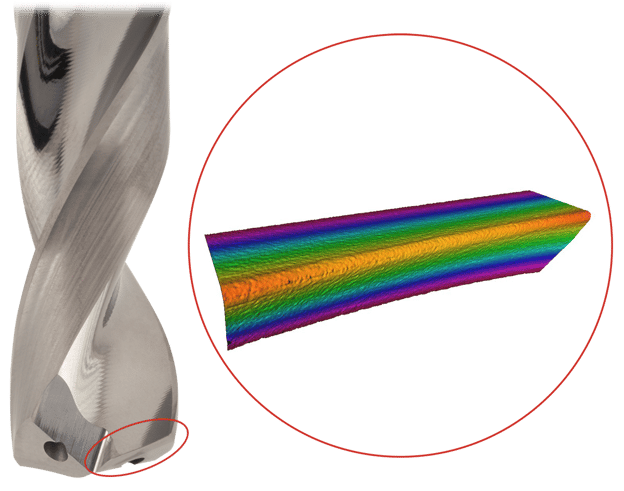

-Carbide tools: the honing on these tools is usually very low, in the order of a few thousandths of a millimeter. This is because the integral carbide is machined with diamond wheels, which create micro irregularities on the cutting edge and could create irregularities in the tool life. The micro-honing applied to the cutting edge of these tools makes the cutting edge constant and leads to a consistent tool life and finish.

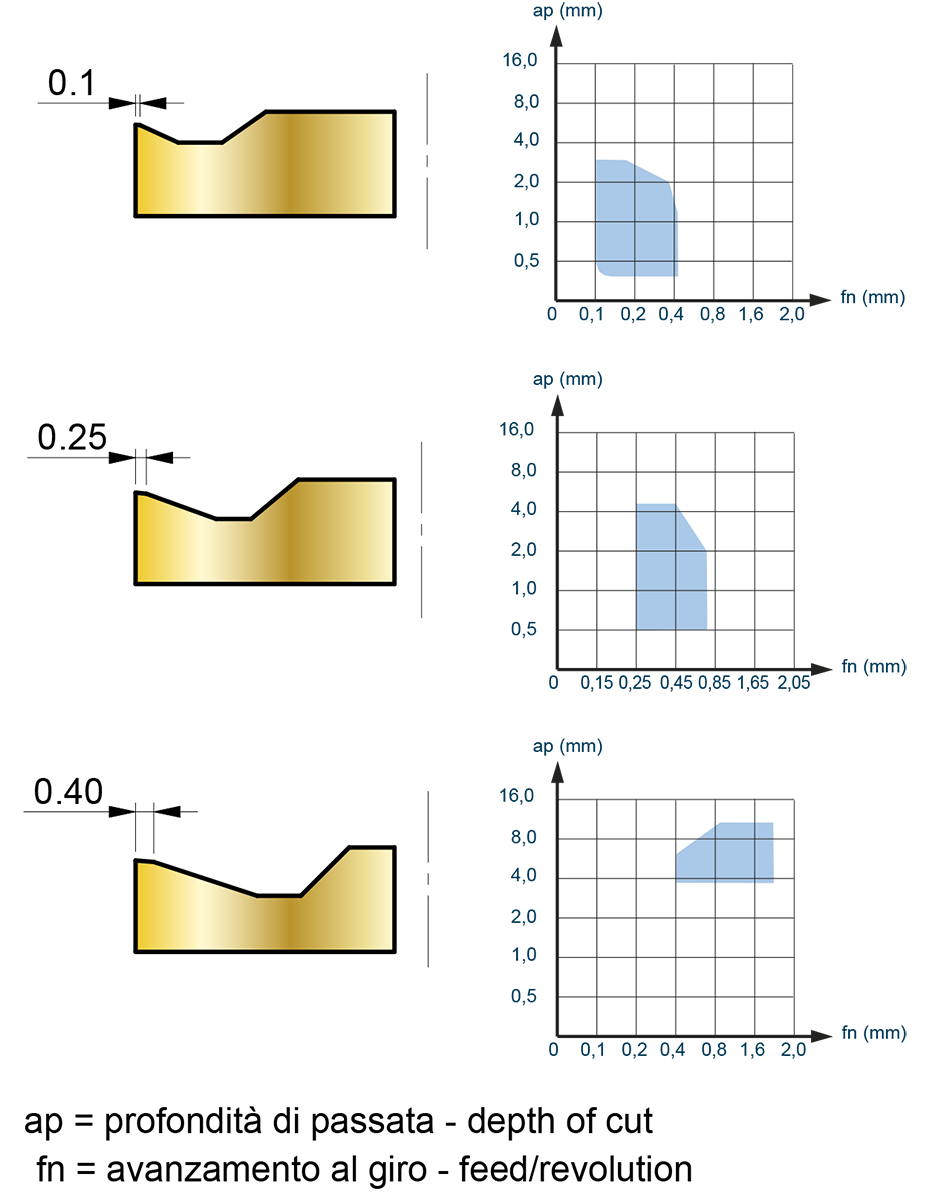

- Turning and milling inserts: in these cases, honing can even exceed one tenth of a millimeter. This type of honing is often used for machining that requires greater strength, such as in the case of difficult-to-machine materials.

- Stainless steel: for this specific material, the honing has an even more critical role. Stainless steel tends to be particularly resistant to wear and heat, so a well-made honing can make the difference in terms of operational efficiency and tool life.

The impact of the honing on the minimum feed

A key aspect of the honing is its influence on the minimum tool feed.

The minimum feed is the amount of material that the tool can remove per turn, and a well calibrated honing can determine how much this feed should be reduced or increased.

For example, if the honing of the tool is 0.15 mm, this will be about the minimum feed of the tool during the cutting operation. This parameter is crucial to ensure accurate machining and to prevent the tool from being prematurely worn or the cut from being uneven.

SAU advanced technology for honing

We have a specific machine dedicated to the honing of tools and inserts in integral carbide, which allows us to guarantee a constant and controlled quality for each single piece.

Thanks to this technology, we can customize the honing according to the specific needs of each application, whether it is a roughing, finishing or other type of processing and material.

Honing advantages for tools

Honing offers a number of significant advantages for cutting tools, let us look at them together.

- More strength of cutting edge

Honing helps to create a more resistant cutting edge, reducing the risk of chipping and extending the tool’s service life.

- Control of cut

Honing helps to create a more resistant cutting edge, reducing the risk of chipping and extending the tool’s service life..

- Constant tool life

Honed tools tend to maintain their performance for a longer period of time (improving tool life), reducing the need for frequent replacements and optimizing production times.

- Roughness

They improve the quality of the worked surfaces thanks to a more constant cut over time.

Conclusions on honing

In summary, honing is a crucial process to improve the performance of cutting tools, directly affecting the quality of processing and the service life of the milling cutters.

Thanks to its advanced technologies, SAU is able to offer tailor-made solutions for every need, guaranteeing excellent results in any type of processing.

To find out more about our honing technologies and how they can improve your manufacturing processes, contact us today.: https://sautool.com/en/contact-us

SAU - Quality Tools Engineering since 1982.