Sau Carbide Flat Head Drills - SD1800

The carbide flat head drills with new Bronze coating by Sau represent an innovative solution in the world of drilling.

Thanks to the new Bronze coating, Sau allows high performance with results of sure importance and the great success they are experiencing in the World Wide market is an evidence to this.

All Sau products are strictly Made in Italy.

Continue reading.

Features of Sau Flat Head Carbide Drills - SD1800

Flat-head drills are produced from a single solid carbide cylinder in nanograin. For the construction high performance and latest generation grinding wheels are used to ensure superior surface finishes.

Thanks to the use of Carbide in nanograin, you get better performance than larger grains, this increases the hardness while maintaining an excellent toughness, adapting to all processing.

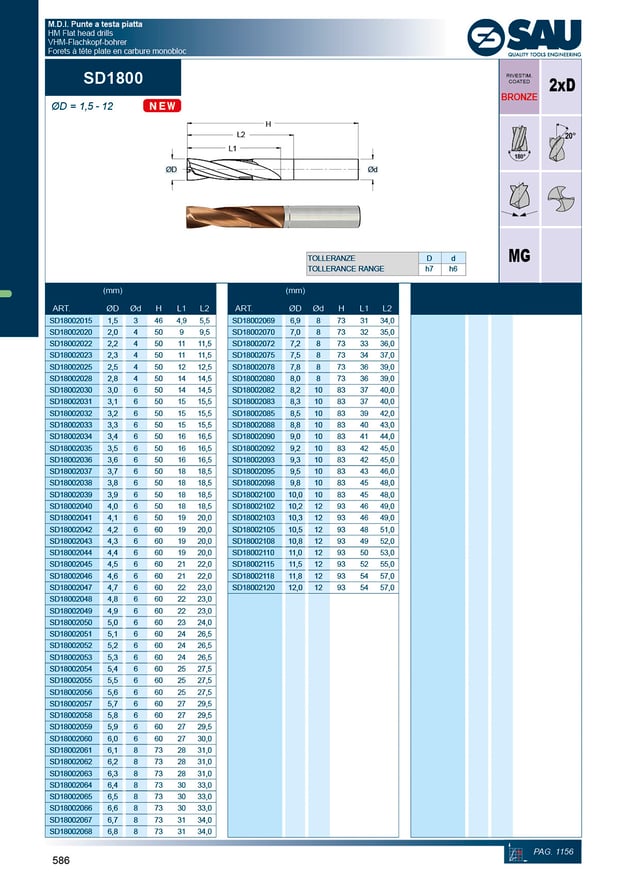

The in-house production offers a wide range of 2xD diameters but, thanks to the Special Department, we are able to produce all the required sizes.

Characteristics of the innovative BRONZE Sau coating

The new Bronze coating is a real news in the metal working view.

Thanks to the dynamic Research and Development Sau department, a more resistant coating and a high hardness with low roughness has been obtained, which allows for an improvement in chip evacuation compared to competitors.

The innovative bronze coating and optimized cutting shape have greatly improved chip evacuation while maintaining stable machining with excellent dimensional tolerance.

Applications and Materials of the Sau Flat Head Solid Carbide Drills

The applications of Carbide flat head drills find optimization of processing on materials such as: all types of steels, cast iron, non-ferrous materials, in addition to very hard materials with adjustments in the processing parameters.

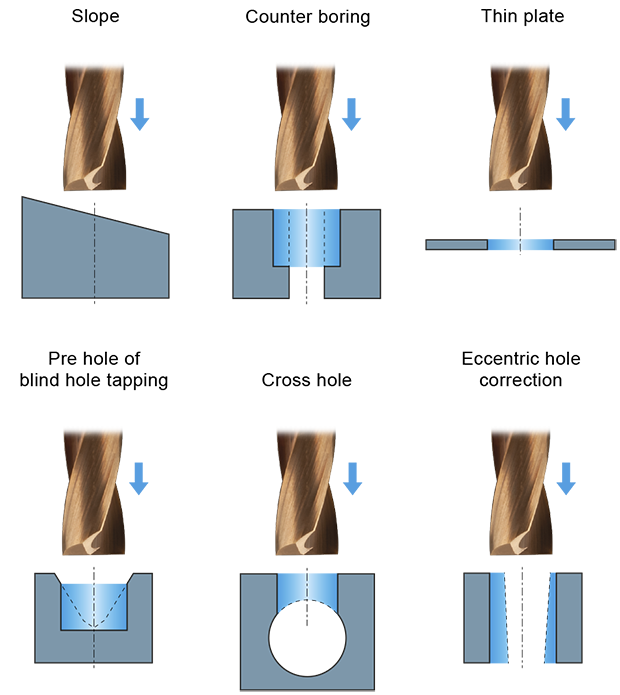

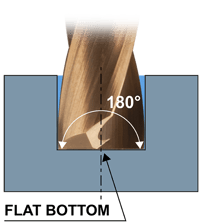

Applications: drilling on an inclined plane even greater than 30°, spot-face on existing pre-hole, thin surface drilling, cross-hole drilling, flat-bottom drilling at 180° and eccentric pre-hole correction.

They can perform even on inclined planes above 30 degrees by changing the parameters.

Application areas for Sau Carbide Flat Head Drills

The flat-head carbide drills with innovative bronze coating are used in the automotive, agricultural machinery, earth handling, automation and in general in sectors where the preparation of flat bottom for recessed TCCE/TCEI screws (allen screws) is required.

Sau special Department

Thanks to its great dynamism and flexibility, Sau Special Department is able to guarantee record times for the creation of custom products thanks to a know-how accumulated over 40 years of experience.

Sau is able to produce special products, even for flat-headed drills, such as step-shaped drills, bits on holes and bevels or drills with different and particular diameters.

Contact our experts for more information.

Sau Team

SAU - Quality Tools Engineering since 1982.