In the machining of the roughing holes, the type of material on which the processing is carried out is a determining factor in order to be able to choose correctly the tool and the insert useful for the machining.

We know how important is the speed of the working cycles and the precision of execution in series for the companies specialized in mechanical processing.

This is the reason why SAU has enriched its range of inserts for boring and reaming machining, with the new XC inserts, which complete and elevate the offer of SAU products, for all companies looking for tools and inserts useful to optimize the machining cycles on specific materials.

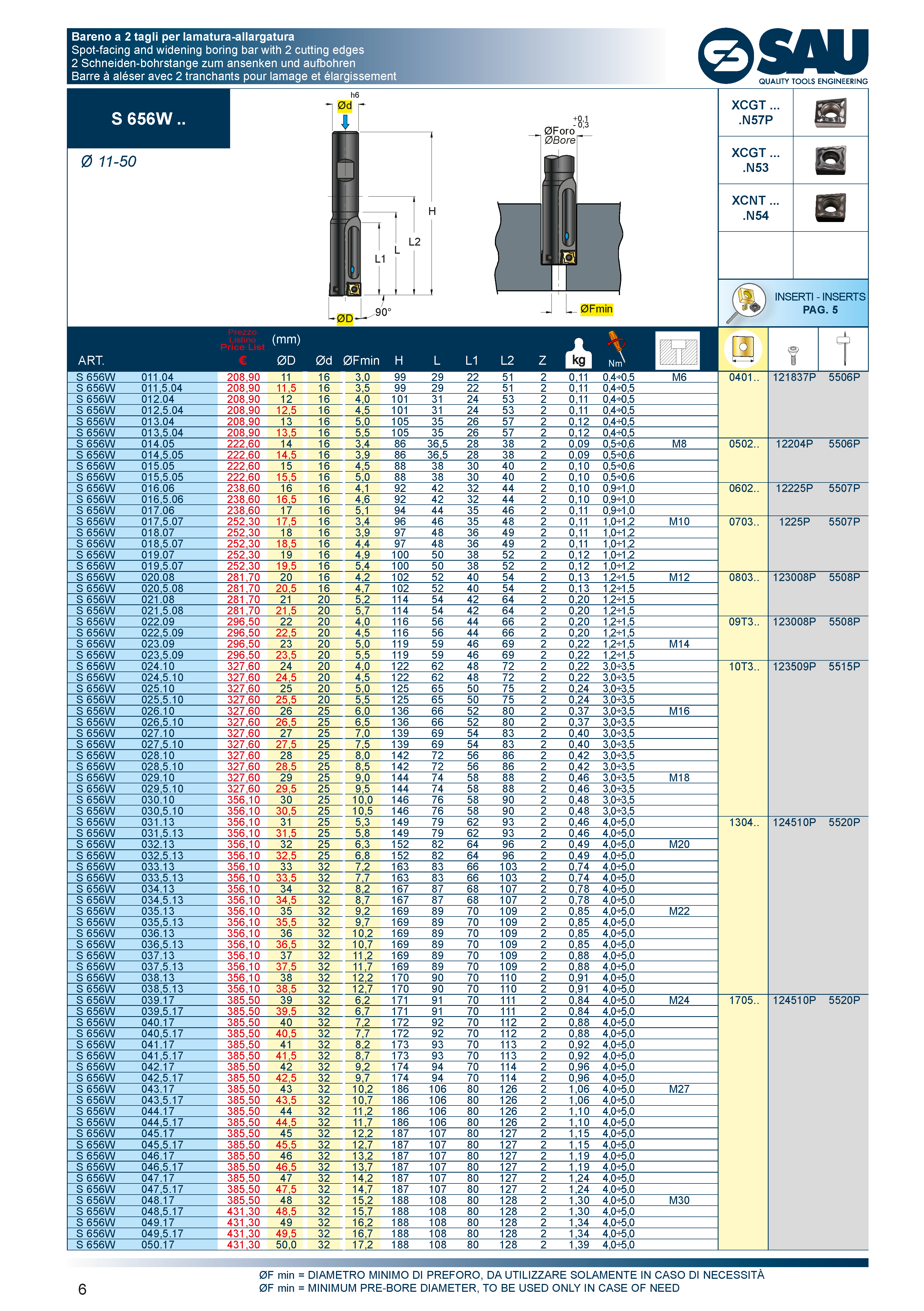

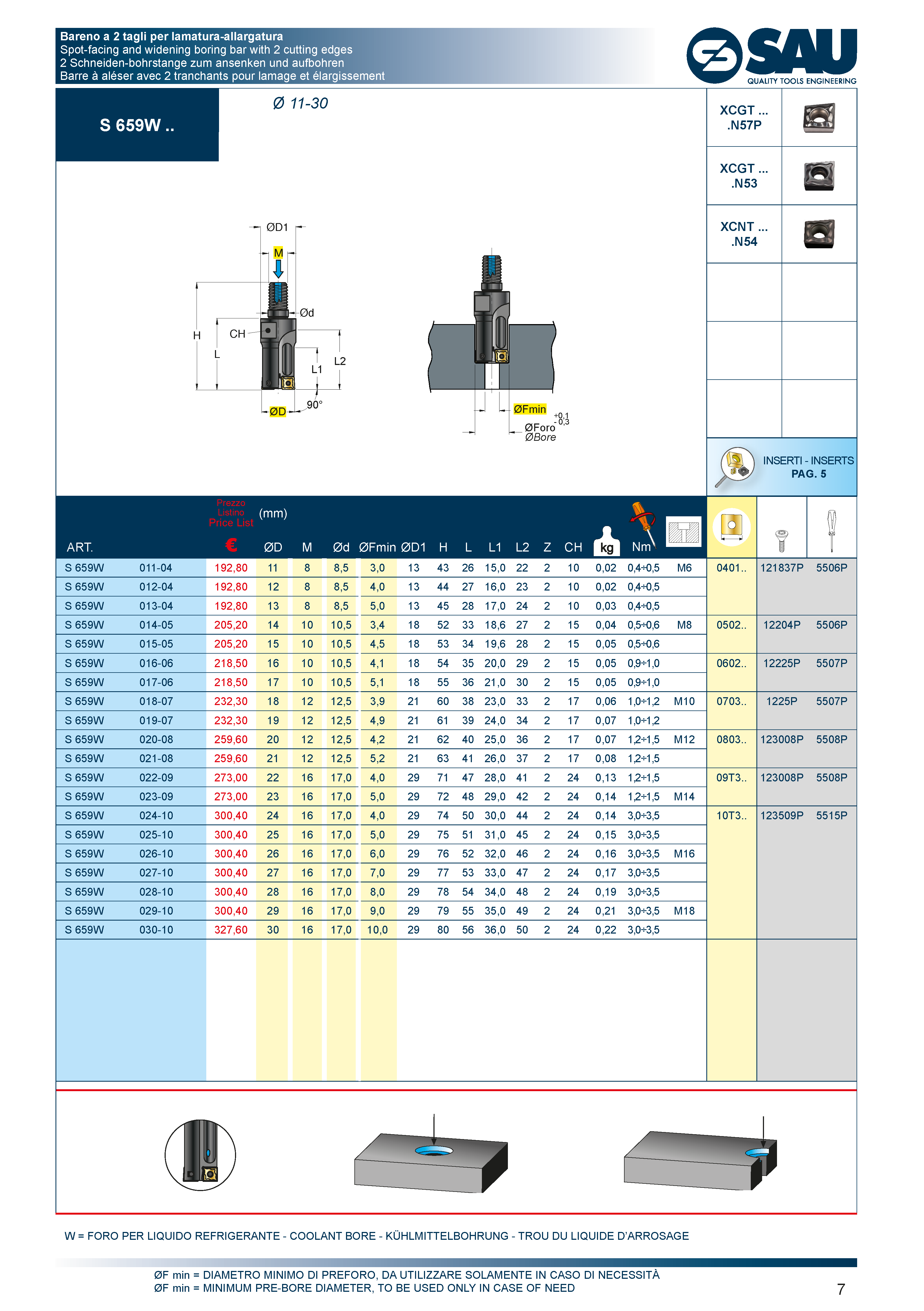

Boring bar for roughing S656

SAU is a company renowned worldwide for the quality of its tools and the know-how of its technicians. For more than 40 years SAU provides the most important companies in precision mechanics in Europe and overseas.

In the range of SAU products, we can count some tools that are unique in the world and are exclusive of the Modena brand.

Among these we can certainly mention the boring bar S656 (and the consequent S659), specific for the roughing machining, tool that has no competitors on the market, due to the advantages brought at the level of performance improvement.

Designed and manufactured for rough machining on pre-existing holes, the S656 boring bar is a particularly rigid tool, with double cutting edge and equipped with a double hole for coolant.

The two cutting edges and the double hole allow an optimal chip control, for a perfect evacuation.

The main use of the S656 boring bar is the realization of seats for embedding heads of socket head screws or TCCE (head of 10, splay of 11 for socket head screw).

SAU is the only company in the world that have such a complete and wide range of this type of bar.

Discover more about our boring system.

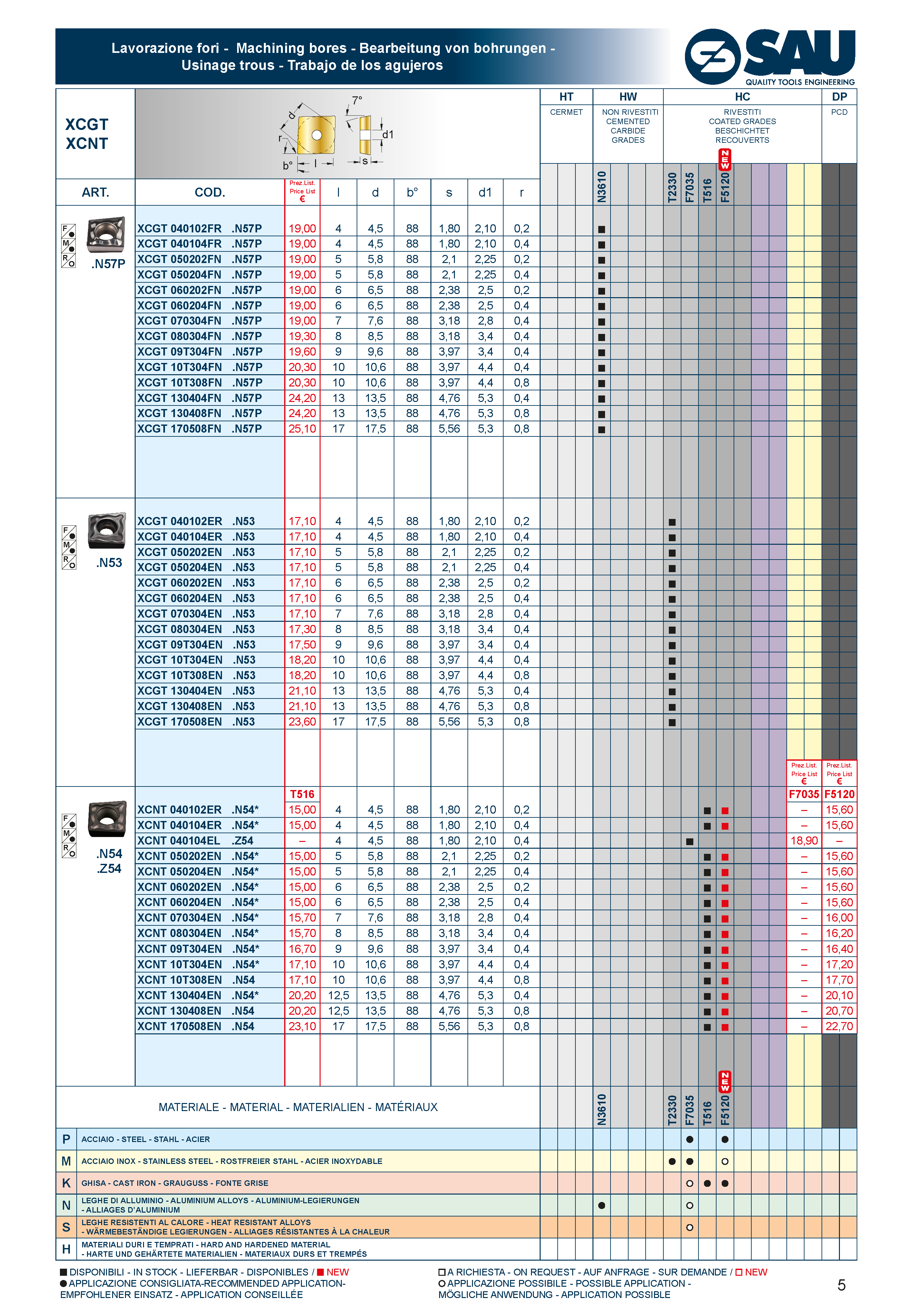

Inserts for XC boring

With the aim of improving the possible applications of the S656 and S659 boring bars, SAU launches its new XC inserts.

SAU technicians have designed inserts that allow to perfect the rough machining on specific materials of use.

The new XC inserts from SAU have a geometry similar to their predecessors, but with new degrees of application, allowing better results in machining performance and much more precise cuts.

The XC inserts are also applicable to the SAU SEC tool, which allows four operations (drilling, internal and external turning, face turning) with a single tool.

Let’s see together what inserts are specifically.

Insert .N57P (XCGT)

The insert . N57P is a polished ground insert (polish), ideal for processing non-ferrous materials, especially aluminum.

Cutting edge is particularly designed to be performed on non-ferrous materials and the particular geometry and polishing makes it particularly suitable for Aluminum processing.

See this page for more information.

Insert .N53 (XCGT)

The insert . N53 is an XCGT ground insert with an ultra-precise tolerance. The application materials are stainless steel and unalloyed steels.

The processing error is clearly contained compared to other inserts. Being ground, we are able to obtain a more powerful cutting edge on the materials, which need a precise cut as stainless steel, unalloyed steel and ISO S materials.

Insert .N54 (XCNT)

The insert . N54 from SAU is an unground insert.

This insert is made with two different grades, allowing a wide range of materials to be processed in a performing way:

- F5120 grade, suitable for processing of ISO P steel materials, but also other materials with hardness above 180 HB.

- T516 grade, designed and manufactured for the processing of ISO K cast iron materials.

Discover more here.

Application of new roughing inserts

The new XC roughing boring inserts add new tolerances to SAU’s range of drilling tools.

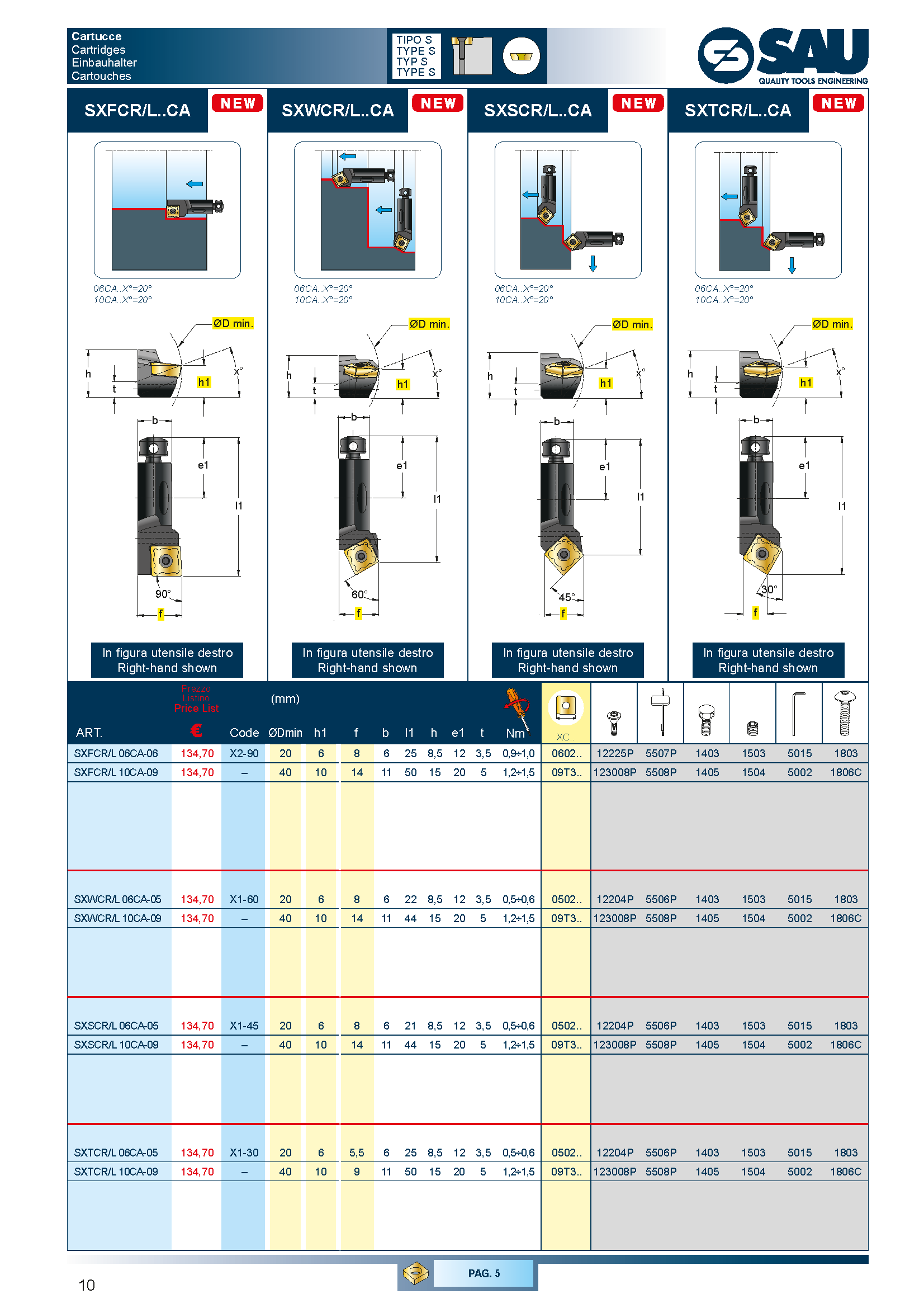

Their application is on tools:

Conclusions

For a better finish and better chip control in the next rough machining of the holes, do not waste precious time.

Contact SAU technicians and ask for information to those who designed the new XC inserts.

You will receive an immediate and free telephone consultation.

SAU - Made in Italy custom tools, since 1982.